Introduction: What we mean by automation in engineering and how we invest

In engineering, automation is the use of technology and robotics to replicate some of the manual operations completed by machinists. It has transformed the way we operate and manufacture high-quality components. At our company, we have embraced automation to streamline our operations and enhance efficiency.

Embracing automation has proven to be a game-changer for us. Since 2019, under new leadership, we have made substantial investments in cutting-edge machinery. However, our approach is careful, and decisions are thoroughly analysed before each purchase.

Prior to acquiring any machinery, we conduct a strategic analysis, evaluating the options and benefits of each machine to make the best investment choices. It became evident that to maximize our output, we had to specify the machine to be as automated as possible. During discussions with machine tool dealers, we would show them the jobs we wanted to machine, and then seek guidance on how to maximise the lights-out running.

Automation initiatives and technologies Ashtead Engineering Company has adopted

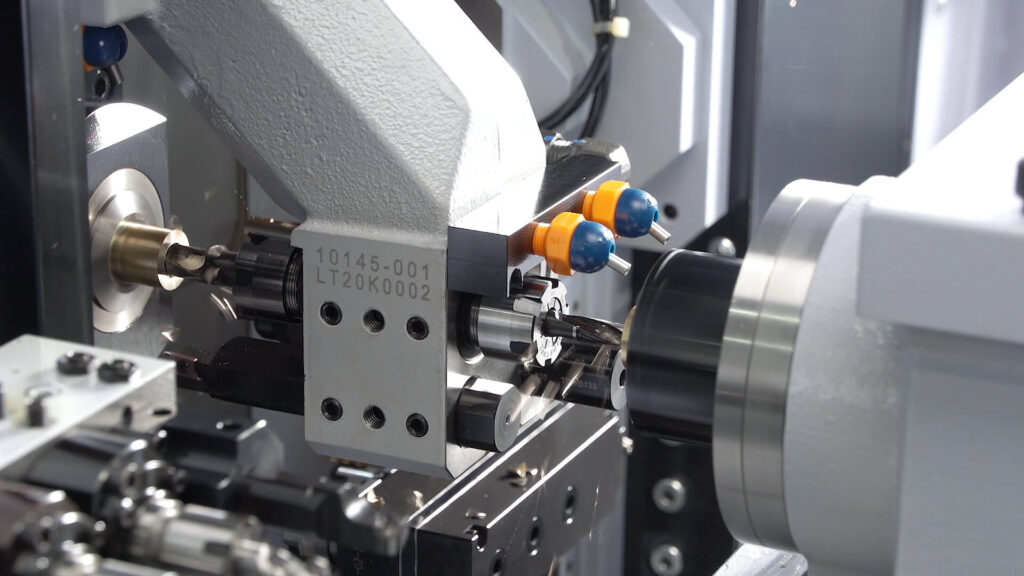

One of the most prominent applications of automation in our facility is the integration of a robot loader. These highly versatile machines tirelessly load raw materials into CNC machines and seamlessly remove finished parts, eliminating the need for constant human intervention. This not only reduces the physical strain on our machinists but also ensures consistent and efficient material handling.

We have also implemented automated bar feeds. These systems tirelessly supply raw material to the CNC machines, ensuring an uninterrupted flow of work and minimising downtime. This automation eliminates the need for manual bar insertion and removal, freeing up our machinists to focus on critical tasks like quality control and programming.

In addition to these physical automation measures, we also employ feedback systems using probing technology. These systems continuously verify that the machine is accurately machining the parts to the specified dimensions. If any deviation is detected, the machine’s offsets are automatically adjusted, ensuring that every component meets the stringent standards of our customers. This feedback mechanism not only maintains precision but also minimises the risk of rework and rejects.

Our commitment to automation extends beyond these specific applications. We are constantly exploring new and innovative ways to integrate automation into our processes, striving to further enhance efficiency, productivity, and quality control. As we advance our automation capabilities, we remain committed to providing our customers with the highest-quality precision engineering components.

How automation has transformed Ashtead Engineering Company

Automation has been instrumental in enhancing our efficiency, productivity, quality standards, and ultimately, our overall business performance.

Increased production and capacity

At Ashtead, we operate a single shift, we have no inclination towards running night shifts. We are utlising automation to run our shift for us! This has significantly increased our production and efficiency, while maintaining overhead costs. However, leaving machines to run un-manned poses challenges in maintaining high-quality standards. We have tackled this problem by utilising in-cycle probing and increasing the frequency of our roaming inspection.

To achieve our long-term business goals and increase our turnover, we have opted for automation instead of adding extra shifts or expanding the size of our factory. Automation has enabled us to almost double our production hours, thereby increasing our capacity and catering to more customers than we could have done previously.

Furthermore, automation has enabled us to expand our product portfolio, venturing into new and more complex machining projects that would have been challenging to undertake with our previous manual operations. This diversification of our offerings has further enhanced our market competitiveness and strengthened our position within the precision engineering industry.

Employee Benefits

As a business, we have seen the positive impact of automation not only on our operational efficiency but also on our employees. By automating repetitive and labor-intensive tasks, our machinists now have the bandwidth to concentrate on strategic initiatives such as quality control, programming, and continuous improvement. It has also empowered them to engage in multi-manning across multiple machines. Our investments have resulted in more competitive pay rates and less man-hours spent, including over-time, making it a win-win situation for both the business and our employees.

Way forward

Ashtead Engineering Company is committed to embracing automation as a strategic imperative that drives our success. Our objective is to make every new machine we purchase as automated as possible. We will continue to invest in cutting-edge machinery, pursue innovation, and develop a skilled workforce to maximise efficiency, productivity, and quality while maintaining a fulfilling work environment. We also believe that this approach will also enable us to provide exceptional value to our customers.