At Ashtead Engineering we offer a full range of CNC and conventional machining services. But what exactly is CNC machining and why is it so popular in the manufacturing and engineering industries?

The introduction of Computerised Numerical Control (CNC) machining in 1952 marked the beginning of a transformative era in precision engineering. This groundbreaking technological development shifted the manufacturing industry from traditional manual methods to automated processes, enabling enhanced precision, streamlined processes, and higher component quality.

Advancing precision: AEC’s evolution in CNC machining

AEC adopted CNC machining in 1982, evolving from humble beginnings with peg-board and cam-auto machines to embracing the then cutting-edge technology of Hebert Husky and Mazak machines. This new technology marked a pivotal turning point, allowing us to offer a significantly more advanced and comprehensive suite of CNC machining services , catering to the diverse needs of our clients.

Over the years, our journey with CNC machining continued to evolve. AEC expanded its CNC capabilities, delving deeper into CNC turning and milling and continuously exploring and integrating the latest technological advancements. Our commitment to excellence led us to consistently invest in the latest modern equipment, reflecting our dedication to maintaining the highest precision manufacturing standards.

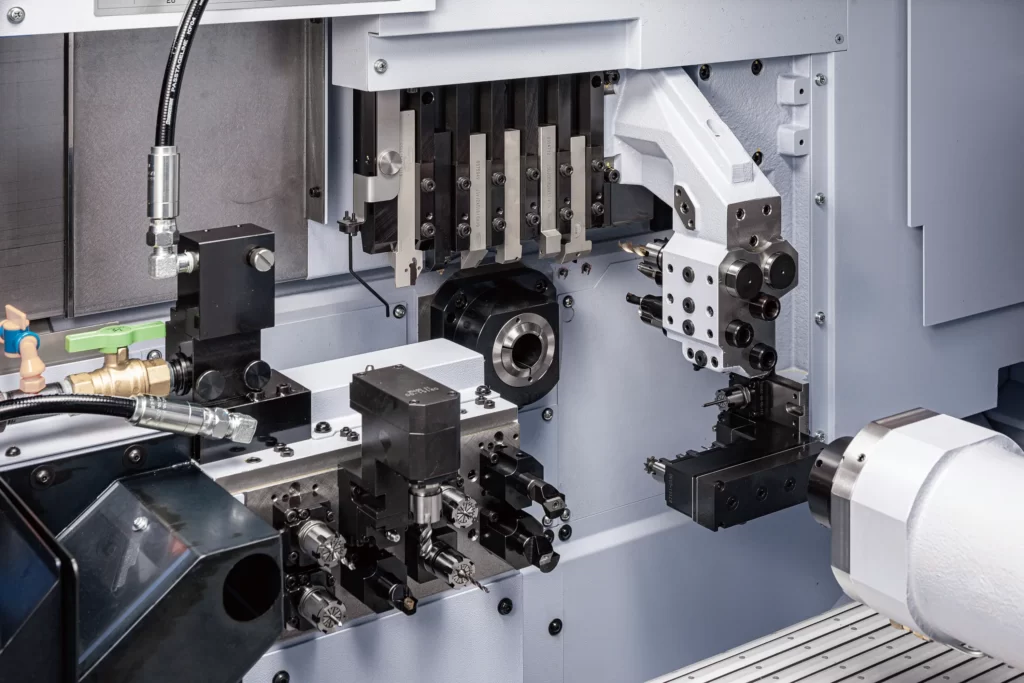

Currently, AEC is at the forefront of integrating robotics and automation into our processes, reflecting our ongoing commitment to efficiency, accuracy, and meeting the dynamic needs of our clients. As we look towards the future, AEC remains poised to embrace emerging technologies, ensuring that our clients benefit from the latest innovations in precision engineering.

Basics of CNC

The manufacturing industry was forever transformed by CNC machining which enabled the automation of a process that previously required engineers to manually wind handles to move the machine axis. The modern day process involves using computer programs to control the movement of machine tools, which has made the process more efficient and accurate.

CNC machines are used widely in turning and milling, but you can also use them in grinding, assembly, and other forms of machinery. A computer can move multiple axes simultaneously, creating more complex shapes, making it possible to manufacture parts and components that were not previously possible without specially-made form tools. The manufacturing process starts with a digital design of the part or component. This design is then converted into a set of instructions that the CNC machine can understand. These instructions are then sent to the machine, which uses them to control the movement of the machine tools.

What is CNC milling?

CNC milling is a subtractive manufacturing process that involves the use of computer-controlled machines to remove material from a workpiece. The process starts with a digital design of the part or component that needs to be manufactured. This design is then converted into a set of instructions that the CNC machine can understand.

The CNC machine uses these instructions to move the cutting tool along the X, Y, and Z axes to remove material from the workpiece. The cutting tool can be a drill, end mill, or any other tool that can remove material from the workpiece. The CNC machine can also rotate the workpiece to create complex shapes and contours.

Advantages of CNC machining

CNC machining has become the norm in the manufacturing industry and has revolutionised many industries by providing numerous advantages over traditional methods.

This mechanism can create shapes and geometries that were previously impossible with traditional machining methods. You can use standard tools to create complex shapes, eliminating the need for specially made form tools, saving time and reducing production costs.

CNC machining also reduces the number of operations required to produce a part. With modern CNC machines, you can perform multiple operations in a single setup, reducing the time and cost of production. Some of the critical benefits include precision, repeatability and scalability:

Precision

You can achieve high accuracy and consistency, which is impossible with manual machining. This precision is essential in aerospace, medical, and automotive industries, where even the slightest error can have severe consequences.

Repeatability

Once you have programmed a CNC machine, you can produce identical parts repeatedly without any variation. This consistency is crucial in mass production, where you need to produce a large number of parts with the same specifications.

Scalability

It allows manufacturers to produce parts quicker, which makes mass production viable, economical and efficient.

Components and working

The structure of a CNC machine is similar to that of a manual machine, comprising a spindle, work holding, axis, tool holding, and more. However, the key difference is that a motor powers the movement of the axis, and there is feedback in the form of an encoder or linear scale gauge, allowing the computer to control it.

The spindle is responsible for rotating the cutting tool or chuck, while the work-holding component secures the machined material in place. The axis component controls the movement of the cutting tool in different directions. On the other hand, the tool-holding component secures the cutting tool in place and allows for easy replacement.

CNC machines have a control panel that allows the operator to input commands and adjust settings. This panel may include a screen for displaying information about the machining process, as well as buttons for making adjustments.

Overall, the major components of a CNC machine work together to automate the machining process and produce high-quality parts with minimal human intervention.

Conclusion

CNC machining is the backbone of modern manufacturing. It is an indispensable tool used in everything, from the production of smartphones to machining for various industries. The technology has seen significant advancements, resulting in streamlined processes and improved efficiencies.

The aerospace, automotive, medical, and electronics industries rely heavily on CNC machining. It has made it possible to produce complex designs and shapes that were not possible with traditional manufacturing methods. It benefits large industries such as oil and gas and aerospace but also makes products more accessible to consumers (which we often take for granted).

By taking advantage of modern CNC machining manufacturing processes are significantly more economical, reducing waste and increasing productivity. It has enabled manufacturers to produce high-quality products at a lower cost, making them more competitive in the market.

With its unmatched precision and accuracy, CNC machining has redefined modern manufacturing, transforming production processes, making them not only more efficient but also more cost-effective. The importance of CNC cannot be overstated, and it will continue to be a driving force in the future of manufacturing.

Explore the power and precision of CNC machining with our state-of-the-art equipment